(click for direction)

Emergency Number: 0409 900 902

Forklift Tynes or Tines

What are forklift tynes?

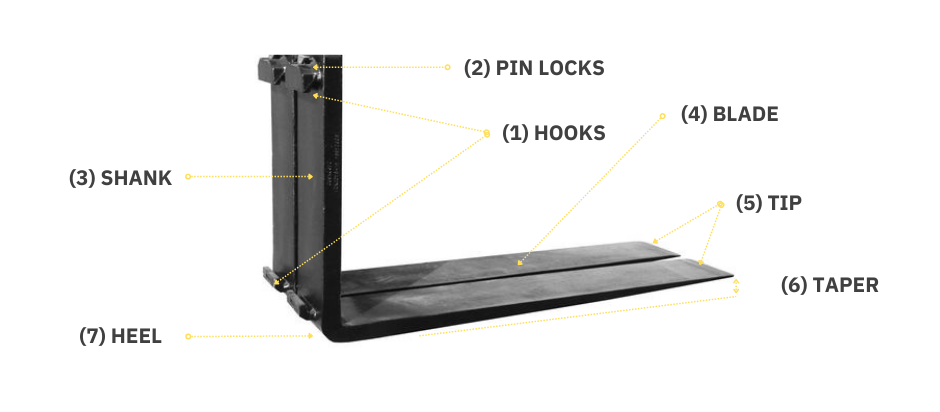

Extending from the base is the (3) shank, which is the vertical section that provides height and stability as the load is lifted. The horizontal part of the tyne, known as the (4) blade, is crucial as it directly supports and lifts the load. This blade is typically flat and smooth to easily slide under pallets and other types of cargo. At the (5) tip of the blade, there is often a slight upward curve or point, which helps to secure the load and prevent it from sliding off during movement. The (6) taper refers to the difference in thickness between the thickest part - (7) heel and the thinnest part (5) tip of the tyne. The thinner tips can fit into tighter spaces between pallet boards or into the openings of other types of cargo containers. These features work together to ensure the forklift operates efficiently and safely in a variety of material handling environments.

How to choose the right size of tynes for a forklift?

Choosing the right size of tynes (or forks) for your forklift involves considering several factors to ensure safe and efficient operation. Here are the key considerations -

- Forklift Capacity - Each forklift has a maximum load capacity, which is usually listed on the data plate along with other important specifications. The size and capacity of the tynes should not exceed the maximum load that the forklift can handle.

- Load Characteristics - Consider the size, weight, and type of loads you will be lifting. The tynes should be long enough to fully support the load without risk of tipping. Generally, the forks should reach all the way under the load, extending slightly beyond it.

- Fork Dimensions

- Length -The length of the tynes should be chosen based on the depth of the load. Typically, the forks should be at least two-thirds the depth of the load.

- Width - The width of the tynes should be appropriate to handle the load securely. Wider tynes might be needed for heavier or larger loads.

- Thickness - This depends on the load weight. Heavier loads require thicker tynes for added strength and durability.

- Forklift Operation Area - Consider the operational environment of the forklift. For example, shorter forks may be necessary if the forklift is primarily used in narrow aisles.

Can forklift tynes be adjusted?

Yes, the pin lock plays a crucial role in attaching the tyne (or fork) to the carriage of a forklift. The pin lock mechanism ensures that the tynes are securely fastened to the forklift’s carriage, preventing them from sliding off during operations. By using a pin that fits through aligned holes on both the tyne and the carriage, the mechanism ensures that the tynes are firmly attached, enhancing the stability of the loads being lifted. This security is crucial not only for the safety of the operations but also for maintaining the efficiency of the workflow, as it prevents the tynes from moving independently of the carriage. Additionally, the design of the pin lock allows for flexibility in the positioning of the tynes, accommodating different sizes and shapes of loads. Operators can easily adjust the tynes along the carriage and secure them in place with the pin, making the forklift adaptable to various tasks without compromising safety or functionality. This simplicity and effectiveness in design make the pin lock a vital part of forklift operations.

How often should forklift tynes be inspected?

Forklift tynes should be inspected regularly to ensure they remain in safe working condition. The frequency of these inspections can depend on the usage and operating environment, but a general guideline includes -

- Daily Inspections - Before each shift, operators should perform a visual check of the tynes for any obvious signs of wear, damage, or deformation. This daily inspection helps identify any immediate issues that could compromise safety during operation.

- Regular Detailed Inspections - Beyond daily checks, more thorough inspections should be conducted periodically, such as monthly or quarterly, depending on the forklift’s usage and the nature of the working environment. These inspections should include checking for cracks, bends, excessive wear, and proper attachment to the forklift.

- Annual Inspections - A qualified professional should conduct a comprehensive inspection at least once a year. This inspection is more detailed and may involve testing and measurements to assess the integrity and functionality of the tynes.

Ensuring that tynes are inspected regularly and maintained properly extends their lifespan and enhances the overall safety and efficiency of forklift operations. Heavy Lift Forklifts provides forklift servicing and forklift repair as well as sells forklift parts for sale and attachments.

What are common problems with forklift tynes?

Common issues include bending, cracking, or excessive wear. These can occur due to overloading, improper handling, or collisions with hard surfaces.

Tynes Wear and Tear

Regular use can lead to wear on the surface of the tynes, particularly at the heels and the tips. This wear can reduce the thickness of the tynes, compromising their ability to safely lift and carry heavy loads.

Tynes Bending

Improper handling, overloading, or collisions can cause the tynes to bend. Even a slight bend can significantly impair the forklift's ability to function properly and safely.

Cracks

Stress from regular or improper use can lead to cracks in the tynes. These cracks are often found at points of high stress, such as the heel where the tyne attaches to the carriage. Cracks can weaken the structural integrity of the tynes and lead to failure during operation.

Fork Misalignment

Continuous use or accidental impacts can cause misalignment of the tynes, making it difficult to safely pick up and transport loads. Misalignment can also increase wear and tear on the forklift's carriage and other structural components.

Corrosion

In certain environments, such as those with high moisture or corrosive materials, tynes can suffer from corrosion. This corrosion can weaken the metal and compromise the tyne's strength and longevity.

What safety precautions should be taken when working with forklift tynes?

When working with forklift tynes, taking appropriate safety precautions is essential to prevent accidents and ensure efficient operation.

Proper Training

Operators must be properly trained and certified to handle forklifts and understand how to safely use the tynes. This includes training on load balancing, fork adjustment, and safe driving practices.

Regular Inspections

Conduct regular inspections of the tynes for signs of wear, damage, or deformation. This includes checking for cracks, bends, and excessive wear, especially at the heels of the forks.

Correct Fork Positioning

Ensure that the tynes are correctly positioned and securely attached to the forklift. Adjust the forks according to the size and shape of the load to distribute the weight evenly.

Load Stability

Always check the stability of the load before lifting. Make sure the load is balanced on the tynes and secured if necessary, to prevent shifting or falling during transport.

Clear Visibility

Operators should always have clear visibility over the load, around the forklift, and along the intended path of travel. If the load obstructs the view, operate the forklift in reverse or use a spotter to assist.

Maintain Safe Speeds

Drive the forklift at speeds suitable for the operating environment and the load being carried. Adjust speeds according to the layout of the workspace, pedestrian traffic, and other factors.

Avoid Overloading

Never exceed the recommended load capacity of the forklift. Overloading can lead to tip-overs and loss of control.

Use Appropriate Personal Protective Equipment (PPE)

Operators and nearby workers should wear appropriate PPE, such as safety shoes, hard hats, and high-visibility clothing.

Follow Manufacturer's Guidelines

Always adhere to the operating instructions and safety guidelines provided by the forklift manufacturer.

---

If you're in need of a new pair of standard forklift tynes, then you've come to the right place. We offer a wide variety of different sizes of standard and specialist tynes for all major forklift brands. To order the correct forklift tynes for your application, simply contact one of our sales experts at (03) 9762 4965 or use our contact form.

At Heavy Lift Forklifts, we have workshops in Melbourne and highly experienced and skilled mobile service technicians. This means we're able to handle the

servicing, repair, and customisation of all forklift tynes in Melbourne and most of Victoria.

Need Forklifts in MElboUrne and VIC?

Don't need to buy! Rent a forklift rental to meet any seasonal peaks.

Quick Links

Contact info

Address:

826 Mountain Hwy, Bayswater VIC

Emergency Number:

0409 900 902

Phone:

(03) 9762 4965

Follow Us On:

Business Hours

- Mon - Thu

- -

- Friday

- -

- Sat - Sun

- Appointment Only

24-hour emergency

Public holidays: Closed

ABN: 55179159792

Payment Options